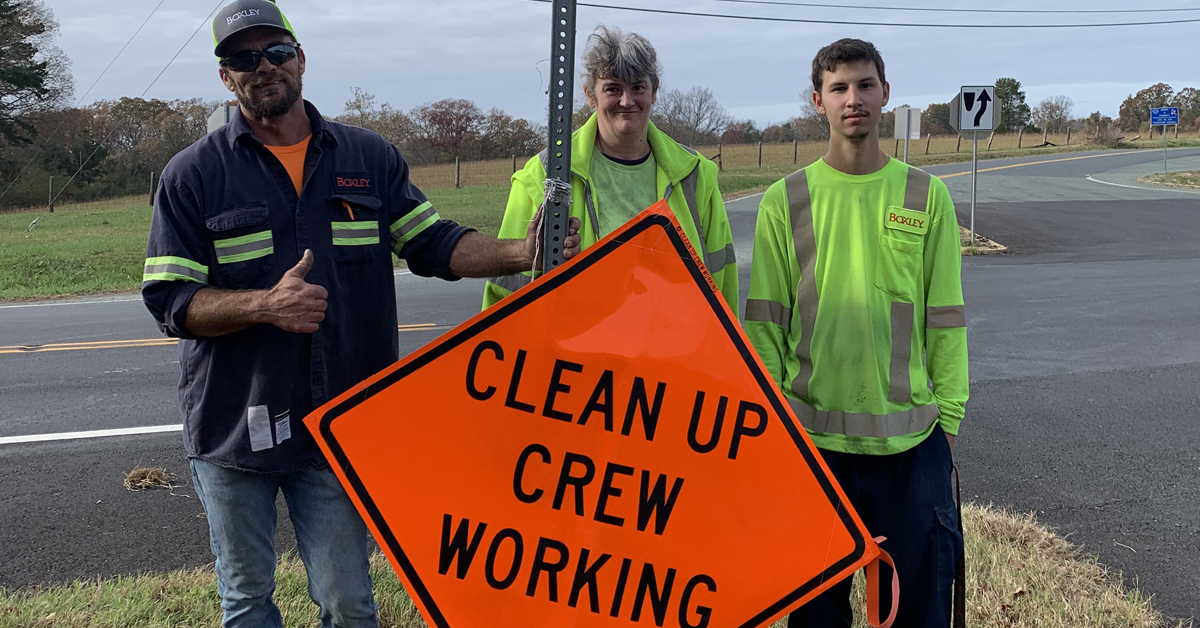

Boxley’s world-class safety program is the cornerstone of the Boxley Way. Our safety culture underpins every facet of our operation, from driver safety to safety-first policies and procedures throughout our operations.

Safety is a value, it’s our first job and how we work.

Each year, we set safety goals and track our performance, emphasizing continuous improvement year over year through our safety mindset and practices. The numbers speak for themselves—our employees take safety seriously. In 2021, Boxley employees worked an outstanding 950,700 hours, during which our fleet drivers drove 2,763,465 miles without a single accident. In addition, our locations underwent their regular inspections, 20 of which were citation-free.

Our work was recently recognized by our parent company Summit Materials. We’re thrilled to add 2021 Top Safety Performer, 2021 World Class Preventable Vehicle Accidents, and 2021 Top 5S Performance to our award collection from previous years.

“Our employees show up every day and put in 100%. This past year we began to see the safety culture we’ve been working hard towards implementing. We know this isn’t the time to let off the gas; we’re looking at 2022 as another year to maintain and improve our safety performance,” said Boxley Safety Director Andy Vassar.

We work hard to keep employees informed on safety events inside the company and across the country. Every incident, good catch, and citation is a learning experience that could prevent another person from getting injured. We incentivize our employees to stay aware of safety hazards and look for ways to improve the work environment for everyone. Our safety culture is an individual and team effort.

Our managers regularly conduct toolbox talks on relevant topics to keep in mind, such as extreme temperature exposure, Boxley’s 10 Safety Principles, unfortunate incidents in the industry, and more. Safety stand-downs are also performed when necessary to really drill home the importance of the safety topic.

“Our employees know that when they have an idea how to make something better, they’re going to be heard,” said Vassar, “We encourage reporting anything an employee has an issue with and promote brainstorming to find the best solution. We want people to feel safe coming to work every day, and most importantly, we want them to go home when they’re done.”

To learn more about Boxley’s commitment to safety, visit our new website (link: ). Also, be sure to follow us on Facebook, LinkedIn, and Instagram